BSWA Array Microphones & Microphone Arrays

2020-12-21

BSWA Company Introduction

Established in 1998, BSWA Technology Co., Ltd. is becoming the preferred supplier for acoustical measurements. With headquarter located in Beijing, BSWA currently employs 100 staffs with branch offices in Shanghai, Guangzhou, and Chengdu. BSWA’s products are distributed in over 40 countries through our sales partners.

BSWA Products cover a full range of acoustic measurement devices. The products are sorted into easy-to-follow sections:

· Microphones

· Micrphone Arrays

· Sound level meter

· Measuring systems

· Material testing

· Audio testing

· Outdoor monitoring systems

· Sound sources

· Cable and accessories

BSWA Array Microphones

BSWA engineers have accumulated 30 years of experiences in making measurement microphones. Each microphone was handcrafted to exacting its high qualities, reliabilities, and extreme stabilities in all kinds of environments.

BSWA micorphones range from 1/1 inch to 1/4 inch in diameter. Among them the MPA231 (or MPA271 with TEDS) 1/2’’ ICCP(ICCP = Integrated Constant Current Power) microphone is for critical applications where high accuracy and low noise are required; The MPA 4*6 series 1/4’’ ICCP microphones are the most cost-effective models for array use. The phases of the microphones are matched according to the customer’s specifications.

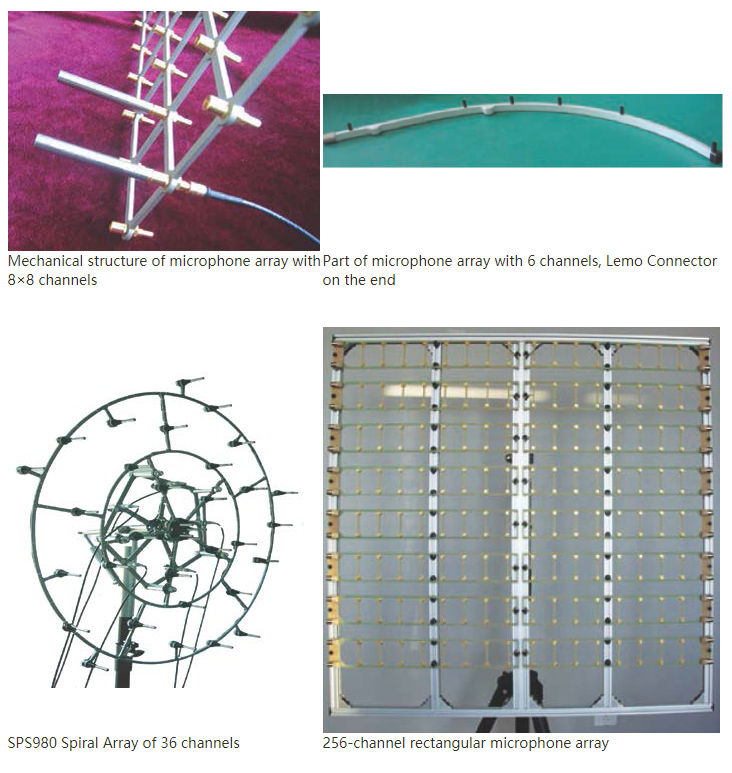

BSWA Microphone Arrays

BSWA designs and manufactures microphone arrays for acoustical measurements. Our experience spans from simple linear array to complicated random array. The number of microphones in the arrays ranges from 16 to 256 according to the customers’ requirements.

Study of array algorithm is a hot topic in the area of both acoustics and signal processing. BSWA can design and produce the microphone array based on the demands of customers.

The following details are required when the customized microphone array is ordered:

· Positions of microphones to be fixed;

· Number of microphone to be used;

· Diameter of microphone to be used;

· Connector type of microphone to be used.

BSWA has the capability to design the mechanical structure, the layout of the cables, and the connector type of the Data Acquisition (DAQ).

To make the array structurally stable, BSWA uses stainless steel (or aluminum) and CNC cutting to fabricate the mechanical parts. The LEMO connectors are used for cables. Each Lemo connector corresponds to several microphones, so that the layout of the cable is very tidy.